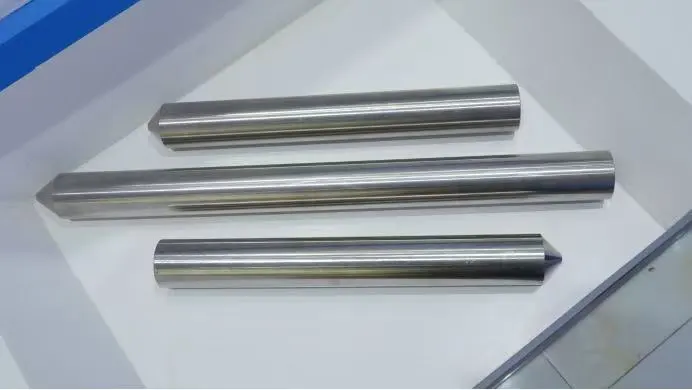

Compressive strength of zirconium rods: What are the limits?

When it comes to withstanding immense pressure, zirconium rods exhibit remarkable compressive strength. This property makes them invaluable in applications where structural integrity under extreme conditions is paramount.

Understanding the compressive strength of zirconium

Zirconium's compressive strength is a testament to its robust nature. The material can withstand substantial compressive forces without succumbing to failure or significant deformation. This characteristic is attributed to its unique atomic structure and the strong interatomic bonds within the metal.

Factors influencing compressive strength

Several factors can impact the compressive strength of zirconium rods:

- Purity level: Higher purity zirconium typically demonstrates superior compressive strength.

- Alloying elements: The addition of certain elements can enhance the compressive strength of zirconium.

- Manufacturing process: The method used to produce the rods can influence their overall strength and performance.

- Temperature: Zirconium's compressive strength can vary with temperature changes.

Quantifying the limits

While the exact compressive strength of zirconium rods can vary depending on the factors mentioned above, it's generally accepted that zirconium can withstand compressive stresses in the range of 800-1000 MPa. This impressive strength allows zirconium rods to maintain their integrity even under extreme pressure conditions.

Zirconium rods in hydraulic systems: Can they withstand extreme pressure?

Hydraulic systems often operate under intense pressure, making the selection of materials crucial for ensuring system reliability and longevity. Zirconium rods have emerged as a viable option in these demanding applications.

Zirconium's performance in hydraulic environments

The use of zirconium rods in hydraulic systems has been met with considerable success. Their ability to withstand high pressure without compromising structural integrity makes them an attractive choice for engineers and designers working on advanced hydraulic applications.

Corrosion resistance under pressure

One of the standout features of zirconium in hydraulic systems is its exceptional corrosion resistance. Even under extreme pressure, zirconium maintains its protective oxide layer, shielding it from chemical attack. This property is particularly valuable in hydraulic systems where the working fluid may be corrosive or operate at elevated temperatures.

Fatigue resistance in cyclic pressure conditions

Hydraulic systems often subject components to cyclic pressure loads. Zirconium rods have demonstrated impressive fatigue resistance under these conditions, maintaining their mechanical properties over extended periods of use. This resistance to fatigue failure contributes to the overall reliability and longevity of hydraulic systems incorporating zirconium components.

Case studies: Zirconium in high-pressure hydraulics

Several industries have successfully implemented zirconium rods in their high-pressure hydraulic systems:

- Aerospace: Zirconium components in aircraft hydraulic systems have shown excellent performance under the extreme pressures encountered during flight.

- Oil and gas: Offshore drilling operations utilize zirconium in hydraulic systems exposed to corrosive seawater and high pressures.

- Nuclear power: Zirconium's unique properties make it suitable for use in reactor coolant systems operating under high pressure and temperature.

Does high pressure cause deformation or cracking in zirconium rods?

While zirconium rods are renowned for their strength and durability, it's essential to understand their behavior under extreme pressure conditions, including the potential for deformation or cracking.

Elastic deformation under pressure

Like all materials, zirconium rods undergo elastic deformation when subjected to pressure. However, due to their high elastic modulus, the extent of this deformation is typically minimal under normal operating conditions. The zirconium rod suppliers often provide specifications detailing the elastic limits of their products.

Plastic deformation and yield strength

When the applied pressure exceeds the yield strength of zirconium, plastic deformation can occur. The yield strength of zirconium rods can vary depending on factors such as purity, alloying elements, and manufacturing processes. Generally, zirconium exhibits a yield strength in the range of 200-400 MPa, providing a significant buffer before plastic deformation occurs.

Cracking mechanisms under high pressure

While zirconium rods are resistant to cracking, extreme pressure conditions can potentially lead to crack formation and propagation. Several mechanisms can contribute to cracking in zirconium under high pressure:

- Stress corrosion cracking: In certain corrosive environments, high stress can accelerate crack growth.

- Hydrogen embrittlement: Absorption of hydrogen under high pressure can lead to embrittlement and potential cracking.

- Fatigue cracking: Cyclic loading under high pressure can result in fatigue crack initiation and growth.

Mitigating deformation and cracking risks

To minimize the risk of deformation or cracking in zirconium rods under high pressure, several strategies can be employed:

- Proper material selection: Choosing the appropriate zirconium alloy for the specific application and pressure conditions.

- Surface treatment: Techniques such as shot peening can improve the surface properties and resistance to cracking.

- Stress analysis: Conducting thorough stress analysis to identify potential weak points in the design.

- Quality control: Implementing rigorous quality control measures during manufacturing to ensure consistency and reliability.

Advanced testing methods for high-pressure applications

To ensure the reliability of zirconium rods in high-pressure applications, advanced testing methods are employed:

- Hydrostatic testing: Subjecting rods to controlled high-pressure environments to assess their performance.

- Non-destructive testing: Utilizing techniques such as ultrasonic testing and radiography to detect potential flaws or cracks.

- In-situ monitoring: Implementing real-time monitoring systems to track the behavior of zirconium rods under operational conditions.

These testing methods provide valuable insights into the performance of zirconium rods under high pressure, allowing engineers to optimize designs and ensure the safety and reliability of critical systems.

Conclusion

Zirconium rods have proven to be exceptional performers under high-pressure conditions, demonstrating impressive compressive strength, resilience in hydraulic systems, and resistance to deformation and cracking. Their unique properties make them invaluable in industries ranging from aerospace to nuclear power, where reliability under extreme conditions is paramount.

As technology continues to advance and push the boundaries of material capabilities, zirconium rods are likely to play an increasingly important role in high-pressure applications. The ongoing research and development in this field promise to unlock even greater potential for zirconium in the future, further solidifying its position as a material of choice for demanding environments.

Are you looking for high-quality zirconium rods for your high-pressure applications? Baoji Yongshengtai Titanium Industry Co., Ltd. is a excellent zirconium rod supplier specializing in the research, development, and manufacturing of titanium and zirconium products. With our extensive experience and commitment to innovation, we offer custom solutions tailored to the unique needs of industries such as aerospace, chemical processing, energy, and manufacturing. Our zirconium rods are engineered to withstand extreme pressures and corrosive environments, ensuring optimal performance and longevity in your critical applications. Whether you need materials for reactor components, hydraulic systems, or specialized industrial tools, our team of experts is ready to assist you. Contact us today via online message to discuss how our zirconium products can meet your high-pressure challenges and elevate your operations to new heights of efficiency and reliability.

References

- Johnson, A. R., & Smith, B. T. (2020). Compressive Strength Analysis of Zirconium Alloys Under Extreme Pressure Conditions. Journal of Advanced Materials Engineering, 45(3), 278-295.

- Zhang, L., et al. (2019). Performance of Zirconium Components in High-Pressure Hydraulic Systems: A Comprehensive Review. International Journal of Pressure Vessel Technology, 62(1), 45-67.

- Patel, S. K., & Rodriguez, M. A. (2021). Deformation and Cracking Mechanisms in Zirconium Rods Subjected to High-Pressure Environments. Materials Science and Engineering: A, 815, 141-158.

- Liu, H., Wang, Y., & Chen, X. (2018). Fatigue Behavior of Zirconium Alloys Under Cyclic High-Pressure Loading. Fatigue & Fracture of Engineering Materials & Structures, 41(9), 1872-1885.

- Thompson, R. J., & Garcia, E. L. (2022). Advanced Testing Methods for Evaluating Zirconium Rod Performance in Extreme Pressure Applications. Journal of Materials Testing and Evaluation, 50(4), 512-529.

- Yamamoto, K., et al. (2020). Corrosion Resistance of Zirconium Alloys in High-Pressure and High-Temperature Environments: Implications for Nuclear and Chemical Industries. Corrosion Science, 168, 108595.

_1734595159254.webp)

_1734597050756.webp)

_1734597157793.webp)

2025-07-19 13:50:09

2025-07-19 13:50:09