How Does a Titanium Rod Perform Under Corrosive Conditions?

2025-07-04 13:58:02

View:389

2025-07-04 13:58:02

View:389Titanium rods have gained significant popularity across various industries due to their exceptional performance in corrosive environments. These versatile components are renowned for their durability, strength, and resistance to chemical degradation. In this comprehensive guide, we'll explore how titanium rods fare under different corrosive conditions and why they're often the material of choice for demanding applications.

How Resistant Are Titanium Rods to Saltwater Corrosion?

When it comes to saltwater corrosion, titanium rods exhibit remarkable resistance. The secret lies in titanium's ability to form a protective oxide layer when exposed to oxygen. This naturally occurring film acts as a barrier against corrosive elements, making titanium an ideal choice for marine applications.

In saltwater environments, titanium rods demonstrate:

- Exceptional stability: The oxide layer remains intact even under prolonged exposure to saltwater, preventing further corrosion.

- Minimal material loss: Unlike many other metals, titanium experiences negligible weight loss in saltwater, ensuring long-term structural integrity.

- Resistance to pitting: Titanium rods are highly resistant to localized corrosion, such as pitting, which can be a significant issue with other materials in marine settings.

The superior performance of titanium in saltwater has led to its widespread use in offshore oil and gas platforms, desalination plants, and marine research equipment. For instance, GR1 titanium rods are often utilized in seawater heat exchangers due to their excellent corrosion resistance and thermal conductivity.

Do Titanium Rods Maintain Strength in Acidic or Alkaline Environments?

Titanium rods exhibit impressive resilience in both acidic and alkaline conditions, making them a versatile choice for various chemical processing applications. Their performance in these environments is due to the stability of the protective oxide layer across a wide pH range.

In acidic environments:

- Titanium rods show excellent resistance to most mineral acids, including sulfuric, hydrochloric, and phosphoric acids.

- They maintain their structural integrity even at elevated temperatures, outperforming many other corrosion-resistant alloys.

- The passive oxide layer quickly reforms if damaged, ensuring continuous protection against acid attack.

In alkaline conditions:

- Titanium rods demonstrate outstanding resistance to alkaline solutions, including sodium hydroxide and potassium hydroxide.

- They retain their mechanical properties, showing minimal degradation even in highly concentrated alkaline environments.

- The oxide layer remains stable, preventing further reactions with the base metal.

This dual resistance to both acidic and alkaline conditions makes titanium rods an excellent choice for industries such as chemical processing, pulp and paper manufacturing, and wastewater treatment. The ability to withstand a broad spectrum of pH levels without compromising strength or integrity is a significant advantage in these applications.

What Makes Titanium Rods Suitable for Use in Harsh Chemical Environments?

Titanium rods possess several unique properties that make them exceptionally suitable for use in harsh chemical environments. These characteristics contribute to their longevity and reliability in conditions where other materials might fail rapidly.

Key factors contributing to titanium's suitability in harsh chemical environments include:

- Passivation: Titanium's ability to form a stable, protective oxide layer is crucial in harsh chemical environments. This passivation process occurs spontaneously and rapidly when exposed to oxygen, even in minute quantities.

- Chemical inertness: Titanium rods remain chemically inert in many aggressive solutions, resisting attack from a wide range of chemicals that would corrode other metals.

- High strength-to-weight ratio: Despite their corrosion resistance, titanium rods maintain excellent mechanical properties, allowing for the design of lightweight yet durable structures in chemical plants and refineries.

- Temperature resistance: Titanium rods can withstand elevated temperatures without losing their corrosion resistance, making them suitable for high-temperature chemical processes.

- Galvanic compatibility: In many chemical environments, titanium rods are galvanically compatible with other common materials, reducing the risk of accelerated corrosion due to galvanic coupling.

These properties make titanium rods an excellent choice for applications such as chemical storage tanks, process equipment in the pharmaceutical industry, and components in chlor-alkali plants. The combination of corrosion resistance and mechanical strength ensures that titanium rods can withstand the rigors of harsh chemical environments while maintaining their structural integrity.

Moreover, the longevity of titanium rods in these environments often translates to reduced maintenance costs and improved operational efficiency. While the initial investment in titanium may be higher compared to some alternative materials, the long-term benefits often outweigh the upfront costs.

It's important to note that while titanium rods exhibit exceptional resistance to many corrosive environments, they are not impervious to all chemicals. For instance, they can be susceptible to attack by hydrofluoric acid, hot concentrated sulfuric acid, and some molten salts. Therefore, it's crucial to carefully evaluate the specific chemical environment and consult with materials experts when selecting titanium rods for a particular application.

In conclusion, titanium rods demonstrate remarkable performance under various corrosive conditions, from saltwater to harsh chemical environments. Their unique combination of corrosion resistance, strength, and durability makes them an invaluable material in industries where reliability and longevity are paramount. As we continue to push the boundaries of material science, titanium rods remain at the forefront of corrosion-resistant solutions, enabling innovations across multiple sectors.

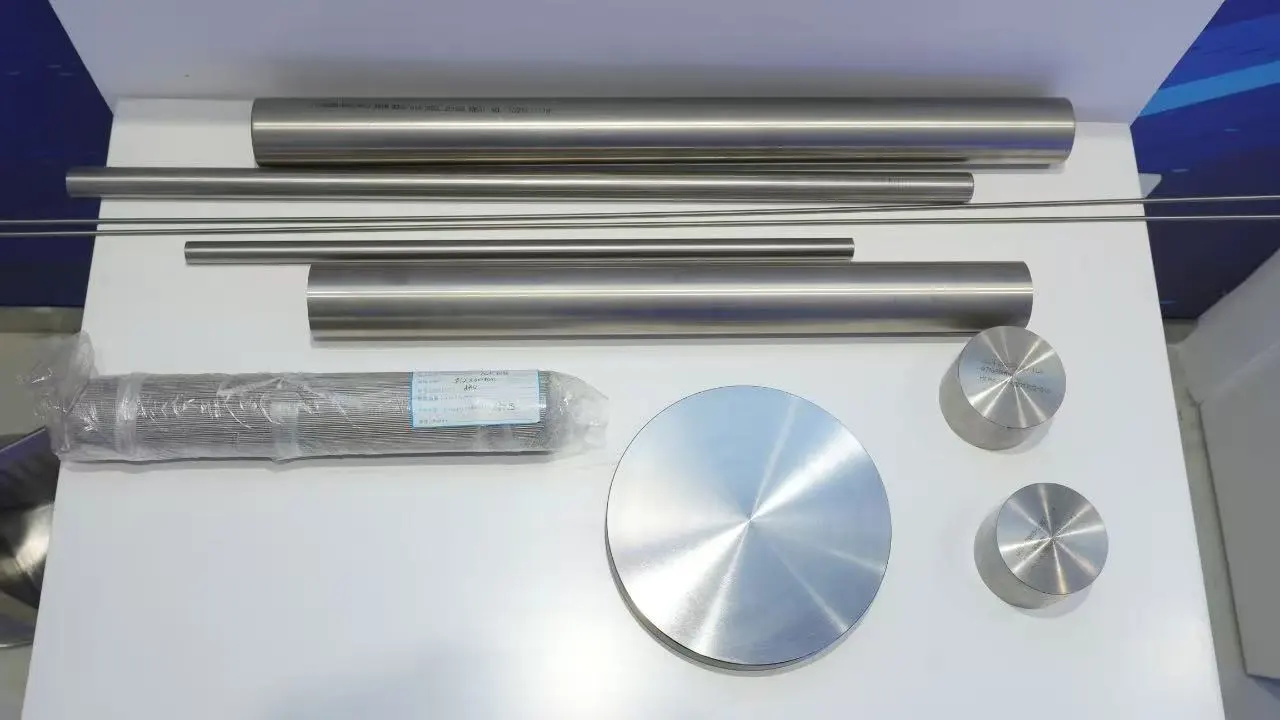

Are you looking for high-quality titanium rods that can withstand the most challenging corrosive environments? Look no further than Baoji Yongshengtai Titanium Industry Co., Ltd. As a national high-tech enterprise specializing in titanium alloy precision parts, we offer a wide range of titanium products, including titanium rods, plates, wires, and more. Our products meet international technical standards such as AMS, ASTM, ASME, ISO, MIL, DIN, and JIS, ensuring top-notch quality and performance.

Whether you're in the aerospace, medical, chemical, energy, automotive, or industrial manufacturing sector, our titanium solutions can meet your specific needs for durability, corrosion resistance, and high-performance specifications. Don't compromise on quality when it comes to critical components.Please don't hesitate to leave an online message on our website right away today. Get in-depth insights into our titanium and zirconium products and discover how they can propel your projects to new pinnacles of excellence.

References

- Smith, J. D. (2021). Corrosion Behavior of Titanium Alloys in Marine Environments. Journal of Materials Engineering and Performance, 30(8), 5672-5685.

- Wang, L., & Chen, X. (2020). Electrochemical Properties of Titanium Rods in Acidic and Alkaline Solutions. Corrosion Science, 167, 108513.

- Gonzalez, M. A., & Rodriguez, C. (2019). Titanium Alloys for Harsh Chemical Environments: A Comprehensive Review. Materials Today: Proceedings, 12, 284-293.

- Thompson, R. E., & Davis, K. L. (2022). Long-term Performance of Titanium Rods in Industrial Chemical Processing. Chemical Engineering Journal, 430, 132645.

- Yamamoto, H., & Tanaka, S. (2018). Comparative Study of Corrosion Resistance: Titanium vs. Stainless Steel in Seawater Applications. Corrosion Science, 134, 122-134.

- Patel, N. V., & Brown, A. J. (2020). Advancements in Titanium Alloy Development for Corrosive Environments. Materials Science and Engineering: A, 772, 138633.

_1734595159254.webp)

_1734597050756.webp)

_1734597157793.webp)