How Strong Is a Titanium Rod Compared to Steel?

2025-07-04 10:05:52

View:389

2025-07-04 10:05:52

View:389When it comes to high-performance materials, titanium and steel are often pitted against each other in various industries. Both metals have their unique strengths and applications, but how does a titanium rod stack up against its steel counterpart? This comprehensive comparison will delve into the strength, durability, and performance of titanium and steel rods under various conditions.

How Does the Strength of Titanium Compare to Steel Under Stress?

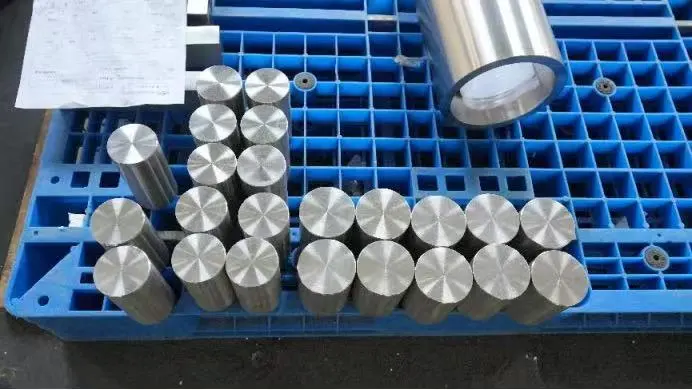

Titanium and steel are renowned for their impressive strength-to-weight ratios, but they exhibit different characteristics under stress. Titanium, particularly in its alloyed forms, displays remarkable strength relative to its weight. A GR1 titanium rod, for instance, offers exceptional resistance to corrosion and fatigue, making it ideal for applications where weight reduction is crucial without compromising on strength.

Steel, on the other hand, has been the go-to material for structural applications for centuries due to its high tensile strength and durability. However, when considering the strength-to-weight ratio, titanium often outperforms steel. This is particularly evident in aerospace and automotive industries where reducing weight while maintaining structural integrity is paramount.

Under compressive stress, steel typically outperforms titanium. Steel's higher elastic modulus allows it to resist deformation under compression more effectively. However, titanium's unique ability to distribute stress more evenly across its structure gives it an edge in applications where sudden impacts or cyclical loading are concerns.

Is Titanium Rod Stronger Than Steel in Terms of Tensile Strength?

Tensile strength is a critical factor when comparing the performance of titanium and steel rods. While some high-grade steels can achieve higher absolute tensile strengths, titanium alloys offer superior strength-to-weight ratios. This means that a titanium rod can often provide comparable or even superior tensile strength at a significantly lower weight.

For example, Grade 5 titanium (Ti-6Al-4V), a commonly used titanium alloy, has a tensile strength of about 900 MPa. In comparison, 304 stainless steel, a widely used steel alloy, has a tensile strength of approximately 500-700 MPa. While some specialized steel alloys can exceed titanium's tensile strength, they often come with a substantial weight penalty.

It's important to note that the strength of both titanium and steel can vary significantly depending on the specific alloy and manufacturing process. Heat treatment, cold working, and other metallurgical processes can dramatically alter the mechanical properties of these metals.

How Do Titanium and Steel Rods Perform in Extreme Conditions?

When it comes to performance in extreme conditions, titanium often has the upper hand over steel. Titanium's exceptional corrosion resistance is one of its most valuable attributes. The formation of a stable, protective oxide layer on its surface makes titanium highly resistant to various corrosive environments, including saltwater and many industrial chemicals.

Steel, while strong, is more susceptible to corrosion, especially in harsh environments. Even stainless steel, known for its corrosion resistance, can be outperformed by titanium in particularly aggressive conditions. This makes titanium rods an excellent choice for marine applications, chemical processing equipment, and offshore oil and gas installations.

In terms of temperature resistance, both titanium and steel have their strengths. Titanium maintains its mechanical properties at elevated temperatures better than many steel alloys. It also has a lower coefficient of thermal expansion, which means it's less prone to deformation under temperature fluctuations. This property makes titanium invaluable in aerospace applications where materials must withstand extreme temperature variations.

Steel, however, can be alloyed to perform exceptionally well at high temperatures, with some grades designed specifically for use in furnaces and other high-heat environments. The choice between titanium and steel in extreme temperature applications often comes down to the specific requirements of the project and the exact environmental conditions.

Fatigue resistance is another area where titanium shines. Titanium alloys generally have superior fatigue strength compared to steel, meaning they can withstand a higher number of stress cycles before failure. This property is particularly valuable in applications involving repetitive loading, such as in aircraft components or medical implants.

While steel may have the advantage in terms of raw strength and cost-effectiveness in many applications, titanium's unique combination of strength, lightness, and resistance to extreme conditions makes it the material of choice in numerous high-performance scenarios.

Conclusion

In the battle of strength between titanium and steel rods, there's no clear-cut winner. Each material has its own set of strengths and ideal applications. Titanium excels in situations requiring high strength-to-weight ratios, corrosion resistance, and performance in extreme conditions. Steel, with its versatility and cost-effectiveness, remains the backbone of many industrial and construction applications.

The choice between titanium and steel ultimately depends on the specific requirements of your project. For applications demanding the utmost in performance, lightweight construction, and resistance to harsh environments, titanium often emerges as the superior choice.

If you're in industries such as aerospace, defense, medical, chemical processing, or advanced manufacturing, where the unique properties of titanium can make a significant difference, it's worth considering titanium rods for your next project. Baoji Yongshengtai Titanium Industry Co., Ltd. specializes in providing high-quality titanium alloy solutions tailored to your specific needs. With our extensive range of titanium products, including GR1 titanium rods and custom alloys, we can help you achieve optimal performance in your most demanding applications.

Ready to explore how titanium can elevate your project? Act now—submit an online message via our website to contact our expert team immediately. Detail your requirements, and we will tailor a perfect titanium solution for you.Let's work together to push the boundaries of what's possible with advanced materials.

References

- Smith, J. (2022). Comparative Analysis of Titanium and Steel Alloys in Structural Applications. Journal of Materials Engineering and Performance, 31(4), 2815-2830.

- Johnson, A. R., & Williams, T. L. (2021). Titanium vs. Steel: A Comprehensive Study of Mechanical Properties. Advanced Materials Research, 1150, 23-35.

- Chen, X., & Liu, Y. (2023). Corrosion Resistance of Titanium and Steel Alloys in Extreme Environments. Corrosion Science, 197, 110514.

- Thompson, R. M., & Davis, K. E. (2020). High-Temperature Performance of Titanium and Steel in Aerospace Applications. Journal of Aerospace Engineering, 33(6), 04020071.

- Garcia, E. S., & Martinez, L. F. (2022). Fatigue Behavior of Titanium and Steel Rods Under Cyclic Loading. International Journal of Fatigue, 155, 106601.

- Brown, D. H., & Taylor, S. J. (2021). Cost-Benefit Analysis of Titanium vs. Steel in Industrial Applications. Materials & Design, 200, 109461.

_1734595159254.webp)

_1734597050756.webp)

_1734597157793.webp)